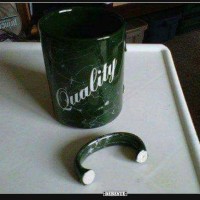

Quality - Keep it simple...!!

Willkommen in der neuen Heimat von Simple-Quality!

Seit einigen Monaten findet hier die Simple-Quality - Community einen festen Platz innerhalb des weltweit größten Netzwerkes für die Produktion, IndustryArena.com

ACHTUNG: Allen Simple-Quality-Mitgliedern haben wir ein temporäres Passwort für den Login zugesendet. Bitte loggt Euch hier mit der Mailadresse und diesem temporären Passwort ein. Nach dem Login könnt Ihr dann ein neues Passwort vergeben und die Registrierung abschließen.

Solltet Ihr Probleme mit dem Login oder der Nutzung haben, sendet uns bitte eine Nachricht.

Wir wünschen Euch hier eine qualitative & stets gute Kommunikation!

Neuer Beitrag im Forum

Prozessfähigkeit CpK

Hallo zusammen, erstmal vielen Dank für eure Anregungen . Ich habe das folgendermassen gelöst, falls jemand vor der selben Herausforderung steht. Ziel der Untersuchung war die Ermittlung eines Cpk von 1.33 bei einer Toleranz von 0 – 0.05mm. In deinem Fall handelt es sich um eine ...

von Bashkimam 09.04.2024 um 12:32 Uhr

von Bashkimam 09.04.2024 um 12:32 UhrNeuer Beitrag im Forum

Kalibrierintervall erweitern (MSA/Prüfmusterabl.)

Hallo TS_PMV, danke für deine Rückmeldung. Die OIML Richtlinie kannte ich noch nicht. Auch noch was dazugelernt. MfG unaware

von unawaream 08.04.2024 um 10:10 Uhr

von unawaream 08.04.2024 um 10:10 UhrNeuer Beitrag im Forum

Kalibrierintervall erweitern (MSA/Prüfmusterabl.)

Hi unaware Danke für dein Feedback und entschuldige für die späte Antwort. Gerne stelle ich allen hier noch eine grobe Zusammenfassung unser Erkenntnisse zusammen und wie wir das in Zukunft handhaben.. - Für den Audit muss der Prozess definiert sein. Die Intervalle können in diesem Prozesse ...

von TS_PMVam 05.04.2024 um 15:19 Uhr

von TS_PMVam 05.04.2024 um 15:19 UhrNeuer Beitrag im Forum

Prozessfähigkeit CpK

Hallo Bashkim, dies ist nicht so einfach zusagen. 1.) Wir kennen die Streung nicht und somit können wir dir auch keine pauschale Antwort geben. 2.) In deinem Fall handelt es sich um eine einseitige Tolerierung und somit ist eine "normale" Prozessfähigkeit mit Normalverteilung mal nicht ...

von QMLEK87am 05.04.2024 um 11:28 Uhr

von QMLEK87am 05.04.2024 um 11:28 UhrNeuer Beitrag im Forum

Prozessfähigkeit CpK

hmm statistische Prozessbeobachtung Ne beschreibung und die Formlen dazu findest du auf jeden Fall im Europa Tabellenbuch Metall. Hab aber leider grad keins zur Hand Gruss sshous

von sshousam 05.04.2024 um 10:00 Uhr

von sshousam 05.04.2024 um 10:00 UhrNeues Thema im Forum

Prozessfähigkeit CpK

Hallo liebe Community, im Zuge meiner Technikerausbildung muss ich die Toleranzen für eine Facette berechnen, die einen Prozessfähigkeitsindex von 1,33 haben muss. Folgende Ausgangslage : Eine Kante mit folgenden Toleranzen, darf nicht breiter sein wie -> 0 - 0.05mm Wie gross darf die ...

von Bashkimam 05.04.2024 um 09:43 Uhr

von Bashkimam 05.04.2024 um 09:43 UhrNeuer Beitrag im Forum

Welche Software für Qualitätsmanagement ?

Hallo, das Wichtigste ist "vorher mitgedacht ist später mit gelacht!" und das ist bei Auswahl von Software extrem wichtig. Nur eine Software für die Verwaltung von Prüfmittel ist die Anschaffung einer Insellösung und nur kurzfristig gedacht. Die Software kann das eine, aber nur das ...

von OliverG_am 22.03.2024 um 13:07 Uhr

von OliverG_am 22.03.2024 um 13:07 UhrNeues Thema im Forum

Welche Software für Qualitätsmanagement ?

Hallo an alle! Wir, Betrieb mit Blechverarbeitung und mechanischer Zerspanung, 180 Mitarbeiter, sind auf der Suche nach einer QM-Software. Diese Software sollte auch den Bereich Prüfmittelverwaltung abdecken. Wird bis jetzt mit Excel durchgeführt, dafür bin ich zuständig. Wer hat da ...

von harweam 22.03.2024 um 08:13 Uhr

von harweam 22.03.2024 um 08:13 UhrNeuer Beitrag im Forum

Abarbeitung bei 8D

Folgende Situation: Unser Kunde (sitzt in Brasilien) hat ein Teil reklamiert mit einem circa Warenwert von so 10 Cent. Ich habe die Reklamation als Lieferantenreklamation weitergereicht. Unser Lieferant (wir kaufen die Teile zu) möchte jetzt natürlich das Schadteil sehen, um eine ...

von 5malwarumam 18.03.2024 um 14:45 Uhr

von 5malwarumam 18.03.2024 um 14:45 UhrNeuer Beitrag im Forum

Vermessung für einen EMPB, welcher Umfang erforderlich?

Hallo, ich sehe das wie Herr Sonntag. Man sollte hinterfragen, warum der Einkauf diesen Lieferanten ausgesucht hat und warum man immer wieder bei diesem Lieferanten bestellt. Es gibt auch so ein Thema wie Lieferantenentwicklung, ist leider in der DIN EN ISO 9001:2015 nicht so schön beschrieben ...

von OliverG_am 15.03.2024 um 14:09 Uhr

von OliverG_am 15.03.2024 um 14:09 Uhr

- Weitere Einträge anzeigen